FCMR32-11-10-SS, Ruland, Stainless Steel clamp style six beam coupling

Metric, Stainless Steel, Beam Coupling, Size: 32

FCMR32-14-10-A, Ruland, Aluminium clamp style six beam coupling

Metric, Aluminium, Beam Coupling, Size: 32

FCMR38-16-16-A, Ruland, Aluminium clamp style six beam coupling

Metric, Aluminium, Beam Coupling, Size: 38

PSMR29-11-11-A, Ruland, Aluminium set screw style four beam coupling

Metric, Aluminium, Beam Coupling, Size: 29

MWC15-5-5-A, Ruland, Aluminium clamp style four beam coupling

Metric, Aluminium, Beam Coupling, Size: 15

MWC20-4-4-A, Ruland, Aluminium clamp style four beam coupling

Metric, Aluminium, Beam Coupling, Size: 20

MWC25-6-6-SS, Ruland, Stainless steel clamp style four beam coupling

Metric, Stainless Steel, Beam Coupling, Size: 25

MWC30-12-12-SS, Ruland, Stainless steel clamp style four beam coupling

Metric, Stainless Steel, Beam Coupling, Size: 30

PCMR19-6-6-A, Ruland, Aluminium clamp style four beam coupling

Metric, Aluminium, Beam Coupling, Size: 19

PCMR25-10-6-A, Ruland, Aluminium clamp style four beam coupling

Metric, Aluminium, Beam Coupling, Size: 25

PCMR25-6-6-SS, Ruland, Stainless clamp style four beam coupling

Metric, Stainless Steel, Beam Coupling, Size: 25

PCMR25-8-8-SS, Ruland, Stainless clamp style four beam coupling

Metric, Stainless Steel, Beam Coupling, Size: 25

PCMR32-12-10-A, Ruland, Aluminium clamp style four beam coupling

Metric, Aluminium, Beam Coupling, Size: 32

FSMR16-6-6-A, Ruland, Aluminium set screw style six beam coupling

Metric, Aluminium, Beam Coupling, Size: 16

This item is not currently available from our stocks.

Despatch date information is on request.

FSMR16-6-6-SS, Ruland, Stainless Steel set screw style six beam coupling

Metric, Stainless Steel, Beam Coupling, Size: 16

This item is not currently available from our stocks.

Despatch date information is on request.

FSMR19-8-8-A, Ruland, Aluminium set screw style six beam coupling

Metric, Aluminium, Beam Coupling, Size: 19

This item is not currently available from our stocks.

Despatch date information is on request.

FSMR19-8-8-SS, Ruland, Stainless Steel set screw style six beam coupling

Metric, Stainless Steel, Beam Coupling, Size: 19

This item is not currently available from our stocks.

Despatch date information is on request.

FSMR25-10-6-A, Ruland, Aluminium set screw style six beam coupling

Metric, Aluminium, Beam Coupling, Size: 25

This item is not currently available from our stocks.

Despatch date information is on request.

FSMR25-12-12-A, Ruland, Aluminium set screw style six beam coupling

Metric, Aluminium, Beam Coupling, Size: 25

This item is not currently available from our stocks.

Despatch date information is on request.

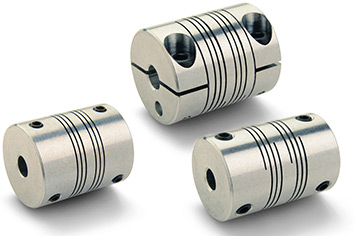

What is a Beam Coupling?

Ruland beam couplings are machined from a single piece of aluminium or stainless steel for a zero-backlash design and maintenance-free service life. Multiple sets of spiral cuts enable the beam coupling to handle all forms of misalignment – angular, parallel, axial motion, and complex – through frequent starts and stops. The multiple-beam design also allows for higher torque and torsional stiffness than commodity-style single-beam couplings.

Ruland manufactures beam couplings in 7075 aluminium for low inertia and 303 stainless steel for increased torque capacity.

Beam couplings FAQs

What are the features and benefits of Ruland beam couplings?

Features & Benefits:

- Zero backlash for accuracy of motion

- Accommodate all types of misalignment

- Balanced for higher speeds and reduced vibration

- Special designs & materials available on request

- All products are RoHS2 and REACH compliant

- Available for immediate despatch

Ruland beam couplings are available with four or six beams in inch, metric, and inch to metric bore combinations ranging from 3/32” (2mm) to 3/4” (20mm).

Can a keyway be added to a FSR style beam coupling

Keyways can help prevent some couplings from slipping on the shaft in high torque situations. We can add a keyway, provided it's a straight bore coupling. We cannot do step bore beam couplings with keyways. The mechanical advantage of using a keyway is to prevent slippage on the shaft in high torque applications. Beam couplings are generally not recommended for use in high torque applications, which is why we don't offer them as standard products with keyways. We would generally guide users towards one of our other types of servo couplings that better fits their application.

What is the axial load that can be applied to a servo coupling?

The Ruland catalogue shows the only coupling that can handle an axial load is a rigid coupling. Any of the flexible couplings, including a beam, will quickly fail. This is a common mistake made with beam couplings, as they look like a spring but do not function like one. Even though Ruland has axial misalignment ratings for all of their flexible couplings, it is only meant to allow for thermal expansion of the shafts. This is a specialised application that requires a different type of coupling.

A Rexnord flexible coupling may better suit applications with greater than normal axial misalignment.