Chain lubrication - The missing link to efficient production

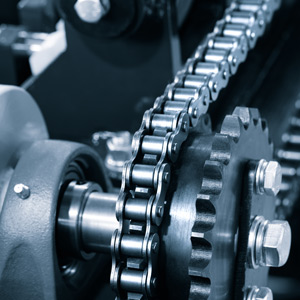

Industrial chains are often overlooked when it comes to component care in machinery; however, chains are vitally important in the production process, and with proper lubrication techniques, can be a key element in maintaining efficient operations.

Why is lubrication important for industrial chains?

Industrial chain comprises a series of precision bearing parts, including inner and outer link plates, bearing pins, bushes and rollers. However, in addition to these well-known components, there is another essential part of the roller chain that is often overlooked: the lubricant.

Industrial chain comprises a series of precision bearing parts, including inner and outer link plates, bearing pins, bushes and rollers. However, in addition to these well-known components, there is another essential part of the roller chain that is often overlooked: the lubricant.

Whether you're performing drag chain maintenance, roller chain maintenance, or otherwise, correct lubrication is both an operative and an economic factor that cannot be overstated, and ensuring chains are properly lubricated is crucial for their longevity. Tests show that properly maintained chains can last up to 60 times longer than chains incorrectly lubricated or not lubricated at all.

Lubrication plays a key role in minimising friction between chain components. This reduction in friction helps prevent wear and tear, which is essential for maintaining the chain's efficiency and extending its operational life.

In approximately 60% of cases, poor or insufficient lubrication is the primary cause of chain failure, making it the single most significant risk factor. Without proper lubrication, the chain is prone to increased friction, which in turn can lead to accelerated wear, resulting in premature failure and necessitating frequent maintenance—the bottom line, increased operational costs.

Benefits of Proper Chain Lubrication:

- Enhanced Efficiency:

- Lubricated chains operate more smoothly, resulting in reduced energy consumption and improved overall efficiency.

- Lubricated chains operate more smoothly, resulting in reduced energy consumption and improved overall efficiency.

- Corrosion Prevention:

- Lubricants create a protective barrier against moisture and contaminants, preventing rust and corrosion.

- Lubricants create a protective barrier against moisture and contaminants, preventing rust and corrosion.

- Heat Management:

- Lubricants help dissipate heat generated during operation, preventing overheating and potential damage.

- Lubricants help dissipate heat generated during operation, preventing overheating and potential damage.

- Noise Reduction:

- Proper lubrication reduces the noise produced by chains, contributing to a quieter working environment.

In Conclusion

Correct lubrication of industrial chain is therefore essential for optimal performance and longevity. Chains that aren't lubricated properly will suffer from increased wear, higher operational costs, and potential damage.

Regular lubrication ensures chains remain efficient, protected from corrosion, and operate quietly, ultimately extending their lifespan.

The improper use of lubrication methods and the application of incorrect lubricants are among the most common sources of trouble. The correct choice of lubricant is imperative for achieving optimal efficiency.

Heavy oils and greases, for example, are too stiff to penetrate deep enough into the chain to reach the actual working surfaces of the chain. Applying grease to the outside of a chain primarily acts as a sealant, impeding the lubricant's ability to efficiently lubricate the parts correctly, which results in greater component wear and ultimately leads to premature chain failure.

ACORN's Lubrication & Adhesives Product Manager, Andrew Howard, has years of experience advising on correct lubrication practices and can provide guidance on best lubrication practices. If you have a question or would like to schedule a site visit, please get in touch with Andrew today.