How do Flender N-EUPEX® couplings reduce downtime?

There’s nothing more important in production than keeping your plant up and running. Downtime can often be costly, resulting in lost production and a reduction in profits. Keeping downtime to a minimum and optimising productivity is a priority in every industry.

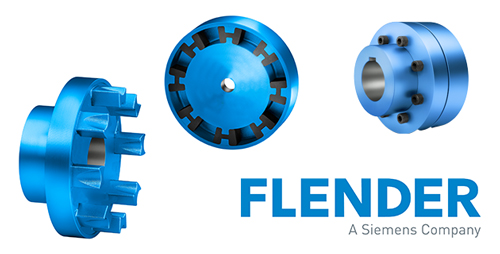

Flender N-EUPEX® pin couplings, also referred to as claw couplings, are renowned across the globe for their innovative design which helps to keep downtime to a minimum. But can a coupling really help you to optimise your productivity?

Here are five of the ways in which Flender N-EUPEX® couplings help businesses to reduce their downtime.

Fail safe design

Flender N-EUPEX® pin couplings showcase a fail-safe design. This means that should the flexible element fail, the coupling will continue to operate without the element until it can be replaced. This ensures maximum operational reliability, keeping downtime to a minimum.

Reduced misalignment

There may be instances where it is not possible to completely eliminate misalignment from your application. This coupling is able to mitigate the effects of shaft misalignment, keeping the impact on surrounding equipment to a minimum and extending service life.

Robust construction

Flender N-EUPEX® pin couplings are manufactured from high-quality cast iron, delivering maximum durability. These couplings are suitable for use in a vast range of temperatures, along with potentially explosive environments. This extreme durability provides the reassurance of reliability in even the harshest of conditions, optimising uptime.

Dampening properties

Vibration and shock loads can be extremely damaging, especially to delicate machinery. This coupling helps to dampen the impact of vibration and shock loads, protecting those delicate surrounding components from the resulting damage and wear.

Reduced wear

Premature component failure is the biggest cause of downtime as machinery has to be shut down for the parts to be inspected and replaced. Flender N-EUPEX® claw couplings feature an innovative design to prevent wear in the metal pins and flexible elements. This helps to keep downtime to a minimum and keep production moving.

Simple installation

Flender N-EUPEX® pin couplings feature a three-part design, enabling plug-in assembly. This reduces the complexity of installation and means that elements can be quickly replaced when required without full disassembly of the shaft.

If you’re looking for a flexible claw coupling which will help you to keep your downtime to a minimum, Flender N-EUPEX® couplings could be the solution. Contact our specialist couplings division today for no-obligation application advice.