GE 4 E, SKF, Radial spherical plain bearing

Metric, Steel/Steel, Without seals, Requiring maintenance, EAN code: 07316577002280

$14.90

In stock

Metric, Steel/Steel, Without seals, Requiring maintenance

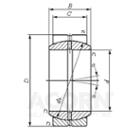

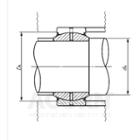

The dimension series of these types conform to ISO standards and they can be used internationally. The outer ring is split at one position.

| ManufacturerProductCode | GE 4 E |

|---|---|

| Basic Product Description | Radial Spherical Plain Bearing |

| Measurement | Metric |

| UOM | Each |

| id (mm) | 4 |

| od (mm) | 12 |

| Width (mm) | 5 |

| Weight (Kg) | 0.003 |

| Lubrication | Requiring maintenance |

| Seals | Without seals |

| Relubrication feature | Without |

| Sliding material, contacting surfaces | Steel/Steel |

| Material, inner ring | Bearing steel |

| Material, outer ring | Bearing steel |

| Basic dynamic load rating | 2.35 kN |

| Basic static load rating | 14.1 kN |

Metric, Steel/Steel, Without seals, Requiring maintenance, EAN code: 07316577002280