With thousands of variations, it is no surprise that deep groove ball bearings bearing is the most commonly used of all the ball bearings. They possess low friction and are optimised for both low noise and low vibration, hence making them capable of running at high rotational speeds.

They are able to support radial and axial loads in both directions, and mounting is quite straightforward compared to other types of bearings. Whether manufacturing or automotive, our deep groove ball bearings are designed to get the job done.

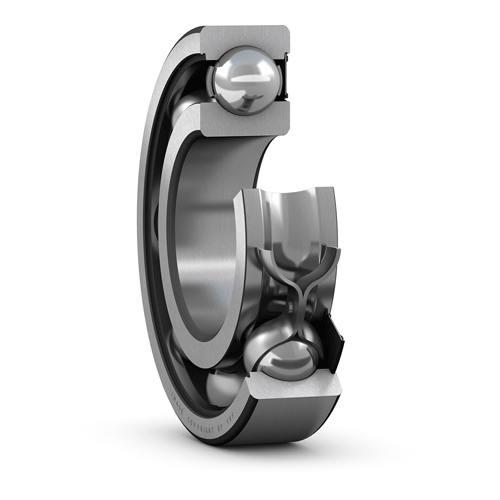

Deep Groove ball bearings have the following features:

An inner ring and an outer ring with deep raceway grooves

Small balls

A cage for maintaining the ball spacing and alignment

By introducing a deeply curved raceway groove, these ball bearings are able to provide stability across higher loads, maintaining high rotational speeds with low friction.

The bearing cage guides the rolling elements and keeps them separate. You will commonly find:

Pressed Steel Cages: These cages are standard for most applications, and are both durable and cost-effective.

Polyamide Cages: These cages are much quieter and lightweight, but are more suited towards lower-temperature applications.

Brass Cages: These cages are resistant to corrosion and are stronger than their counterparts. These cages are capable of handling high vibration and high-speed applications.

There is a range of seals and shields to handle any application or environment:

Shielded: Shielded bearings have metal shields which protect the internals from larger particles. Shields are designed to keep friction to a minimum.

Sealed: Some bearings come with rubber seals, which are excellent at protecting against dust, moisture, and any other contaminants that might affect the components. These seals are maintenance-free and come pre-lubricated.

No Seals: These bearings are best where external lubrication can be applied and where contamination is kept to a minimum.

Some of the key features of deep groove ball bearings that make them versatile and efficient in many fields of application are described below. Here are some of the essential characteristics and their corresponding benefits:

High-Speed Capability: Deep groove ball bearings are designed to operate at very high rotational speed. Therefore, these types of bearings are suitable for applications that involve very fast motion or high-speed rotations. This will reduce the operational downtime and increase productivity since most electrical machines, like electric motors and conveyor systems, depend on this.

Can Carry Relatively High Radial Load: These bearings are designed to bear a good amount of radial load; therefore, this type of bearing is suitable for machinery working under high load conditions. This means durability and extends the life of equipment in manufacturing and automation.

Capable to Bear Axial Load to Some Extent in Both Ways: Although designed basically for radial loads, deep groove ball bearings can accept additional axial loads in both directions. This feature makes them quite versatile, able to perform well in complex systems where forces are applied from multiple angles-such as gearboxes or automotive applications.

Quiet Running: Deep groove ball bearings are optimised for low noise and vibration levels; therefore, they are important in applications where quiet operation is an issue. This makes them very suitable for household appliances, consumer electronics, and medical devices where noise reduction is of prime importance.

Low Maintenance: Deep groove ball bearings require very little maintenance since they are of a construction that is either sealed or shielded. The need to make frequent lubrication and adjustments is hence reduced. This implies an economic advantage since costs will be saved over time. It's most advantageous in environments where regular maintenance is hard or impossible to reach, as may be experienced in some remote industrial areas.

High Running Accuracy: These bearings ensure accuracy during operation; hence, actual smooth rotation is achieved, even at high speeds. Such accuracy is highly intended for use in precision instruments, robotics, and high-performance machinery, where slight inaccuracies tend to cause disruption.

Deep groove ball bearings are one of the most commonly used bearing types due to their versatility, endurance, and performance. Their efficiency in various areas enables them to perform aptly for applications in industries like:

Gearboxes: The bearing supports high-speed rotating shafts that carry heavy radial and axial loads with precision and reliability.

Electric Motors: Allow frictionless motion and rotation with minimum vibration, further enabling silent operation with low maintenance for HVAC, appliances, and general industrial machinery.

Textile Machines: These run at high speeds with low noise and are, therefore, of much importance in the case of efficient and continuous production.

Hand Tools: They offer smooth, frictionless rotation to drills, grinders, and saws by allowing for increased efficiency and tool life.

Automotive: These bearings can be found in wheel hubs, transmissions, and alternators; they guarantee smooth operation in a wide range of automotive applications.

Conveyor Systems: These provide for smooth, high-speed operation within manufacturing plants and warehouses, reducing any instances of downtown.

Consumer Electronics: Provide quiet and precise performance for use in applications like fans, hard disk drives, and printers.

Medical Equipment: Noise-free and precision operation of MRI diagnostic apparatuses and centrifuges that support continuous diagnostics and procedures.

Aerospace: These have precision and reliability in jet engine and flight control applications and are put to use under very extreme conditions at high speed.

Deep groove ball bearings are widely regarded as versatile and reliable due to their ability to handle both radial and axial loads, high speeds, and low maintenance needs.

Deep groove ball bearings are sometimes referred to as "single-row radial ball bearings" due to their common use in applications requiring radial load support.

Yes, deep groove ball bearings are specifically designed to handle relatively high radial loads, making them ideal for many applications where such forces are prevalent.

Deep groove ball bearings can handle moderate axial loads in both directions, though the exact amount depends on the specific bearing design and size.

While not primarily designed for thrust loads, deep groove ball bearings can support light to moderate axial (thrust) loads, depending on the application and bearing type.