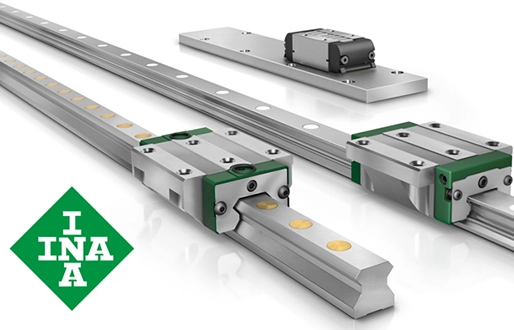

5 Reasons to Consider INA Linear Rails & Carriages for Your Next Machine Build

Selecting the right components is essential to building a machine that performs reliably, efficiently, and with lasting precision. When it comes to linear motion systems, INA linear rails and carriages from Schaeffler offer proven quality and performance. Helping you achieve the accuracy and dependability your build demands.

Here are 5 reasons to make INA linear guides your choice for the next machine or automation project.

1. Precision

With ground raceways, tight preload classes, and smooth recirculating ball guidance, INA linear guides deliver exceptional running accuracy and low friction. This translates to repeatable precision, smooth motion, and consistent cycle quality – all critical factors for applications such as CNC machinery, automation assemblies, and industrial positioning systems.

2. High load capacity and rigidity

INA carriages are engineered to handle high loads and moments in multiple directions, ensuring stiff, stable guidance with minimal deflection. This rigidity enables heavier tooling, faster acceleration, and greater accuracy in machining, cutting, or positioning applications, giving your machine a solid foundation for performance and productivity.

3. Long service life in touch environments

Built for durability, INA linear guides feature robust sealing systems, effective wipers, and proven lubrication concepts that extend service life even in contaminated or high-duty environments. For applications exposed to moisture or chemicals, corrosion-resistant coatings and stainless-steel options provide additional protection. This makes them suitable for demanding sectors such as food processing, packaging, and manufacturing.

4. Versatile & easy-to-integrate

Whether you’re designing a compact precision tool or a large industrial system, INA offers a broad range of sizes, rail and carriage lengths, preload classes, and mounting configurations. This makes it easy to match the right guide to your space, load, and accuracy requirements. Many designs are also interchangeable with common industry footprints, helping simplify retrofits and upgrades.

5. Proven support

With Schaeffler’s comprehensive engineering resources and documentation (and local support from ACORN) you have expert help every step of the way. From correct sizing and specification to reliable supply and fast delivery, we ensure your project runs smoothly. The result? Reduced downtime, lower maintenance costs, and improved machine reliability across the lifecycle.

Build with confidence

INA linear rails and carriages combine engineering precision with ACORN’s trusted local service, giving you the performance, reliability, and support you need to build better machines, faster. Talk to our dedicated Linear Division today about your specifications.