Optimise Your Total Cost of Ownership with Gates Premium Belts

Keeping your operating costs to a minimum is essential to being a profitable business. Whether you operate in the food and beverage industry or in the energy sector, your business needs to make a profit in order to succeed.

It's easy to just look at the initial purchase cost of your equipment and make savings by opting for lower cost components. However, if this then leads to expensive maintenance requirements or regular machine breakdown, you could find yourself spending more in the long run.

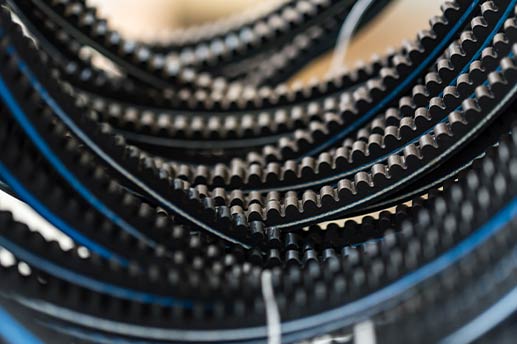

The Gates range of premium belts puts total cost of ownership first. This means that although you may pay more for the initial purchase price of the belt, you could make cost savings throughout its service life.

Let's take a look at how Gates prioritises total cost of ownership with its range of premium belts, and how you could secure long term savings for your business.

Why is total cost of ownership important?

Whatever industry you work in, total cost of ownership is the key to success. Keeping the initial cost of purchase down isn't enough if the components you're choosing are quickly failing and requiring replacement, or if they have high maintenance requirements.

Total Cost of Ownership, or TCO, is about looking at the entire service life of your machinery. That means thinking about the initial purchase cost, any maintenance requirements, its length of service life and the cost of replacement. By understanding the bigger picture, you can begin to make adjustments to reduce your operating costs and make your entire production line more cost-efficient.

Where does Gates come in?

It’s easy to be tempted to look for the lowest price tag when you’re looking for a replacement belt for your machinery. However, we know that this doesn’t always guarantee you a low total cost of ownership, as you may end up paying the price through frequent repair, inefficiency, replacement and maintenance.

Gates' range of premium belts have been specially designed to reduce your total cost of ownership, meaning that you can secure long term savings for your business. They do this in three key ways: by extending the service life of your machinery, by minimising maintenance requirements and by reducing energy consumption.

Let's take a look at how Gates' premium belts can help you to reduce your total cost of ownership.

Extended service life

When you’re specifying a belt for your machinery, the initial purchase price is only one part of the puzzle. You’ll also need to consider how often you’re likely to need to replace the belt, and how often you can expect it to fail. Of course, this will depend on the operating parameters of your machinery, as well as the environment in which your machinery is operating.

Gates premium belts have been designed to deliver an extended service life. Whilst the initial purchase price may be higher than with other belts, you'll notice the long term savings thanks to the increased performance that is delivered.

For example, the Gates Predator® v-belt can transmit up to 2.2 times more power than a standard v-belt. This means that less strain is put on surrounding components, protecting your belt drive from costly damage. The belt will be less likely to be damaged during operation, and many engineers find that they need less v-belts for operation, keeping the drive compact and reducing the quantity of belts that need to be purchased.

For example, the Gates Predator® v-belt can transmit up to 2.2 times more power than a standard v-belt. This means that less strain is put on surrounding components, protecting your belt drive from costly damage. The belt will be less likely to be damaged during operation, and many engineers find that they need less v-belts for operation, keeping the drive compact and reducing the quantity of belts that need to be purchased.

Thanks to its increased power capacity and extended service life, it’s estimated that Gates Predator® v-belts could reduce your total cost of ownership by up to a third – a considerable saving for any business.

Minimised maintenance requirements

Maintenance is both costly and time consuming, but it’s a necessity in the majority of belt drives. Whilst most belts do not require lubrication, they do require regular re-tensioning to ensure that they remain efficient and to minimise slippage.

Unfortunately, regular maintenance can quickly increase your total cost of ownership, especially if that maintenance requires downtime.

Gates’ range of premium belts has been designed to combat this, with minimal maintenance requirements throughout their service life. This is thanks to innovative designs which make use of industry leading materials to prevent elongation and promote performance.

For example, Gates Quad-Power® 4 utilises innovative minimal-stretch cord technology to virtually eliminate maintenance requirements. This means that there’s no run in period or re-tensioning required, extending service life whilst removing any need for downtime.

For example, Gates Quad-Power® 4 utilises innovative minimal-stretch cord technology to virtually eliminate maintenance requirements. This means that there’s no run in period or re-tensioning required, extending service life whilst removing any need for downtime.

Reduced energy consumption

Electric motors represent around 75% of all energy consumed by industry, translating to 45% of global energy consumption. Around a third of all electric motors utilise belt drives, but this type of drive is notoriously inefficient, with many v-belt drives achieving less than 85% efficiency. Not only does this significant energy wastage contribute to global warming, but it’s not great for your bottom line either.

Gates power transmission belts such as Poly Chain® GT® Carbon® deliver up to 99% energy efficiency, meaning that you’re actually using the majority of the energy that is generated by your electric motors. This represents a 5% energy saving when compared to a typical v-belt, combined with around a 30% increase in power.

Gates power transmission belts such as Poly Chain® GT® Carbon® deliver up to 99% energy efficiency, meaning that you’re actually using the majority of the energy that is generated by your electric motors. This represents a 5% energy saving when compared to a typical v-belt, combined with around a 30% increase in power.

This means that you’re only paying for the energy you’re using, minimising your operating costs and maximising your productivity. Not only that, but it’s also a great way to prioritise sustainability in your organisation, contributing to your Corporate Social Responsibility strategy.

Get it right first time

Unfortunately, you can’t just choose a premium belt and fit it onto your machinery. No matter how well-designed the belt is, it needs to be right for your machinery and your operating conditions. If the belt is not suited to the operating environment, you could find it damaged by shock loads, extreme temperatures, or contamination, dramatically shortening its service life.

There’s no one-size-fits-all when it comes to power transmission belts. Every application needs to be looked at as an individual case, with the various options weighed up. This is the only way that you can effectively identify the right belt for an application.

At ACORN, we are proud partners of Gates, supplying their full range of premium belts. But we don’t just supply belts – we go a step further. We want you to be delighted with your belt and really see the effect that it has on your total cost of ownership. That’s why we take the time to get to know our customers, fully understanding exactly how your business works and the challenges that you face, so that we can help you to find the right belt to meet your needs.

If you need help choosing the right belt for your application, or if you need assistance in reducing your total cost of ownership, get it touch with us today. Our power transmission experts are waiting to help!