CASE STUDY: How Smarter Pump Solutions Saved a Local Pool £8,500 Annually

When a local council reach out to Business Development Manager, Lee Dobson, their challenge was clear. With rising energy bills and aging infrastructure, the pumps driving their swimming pools at a busy leisure centre were no longer efficient. They needed a solution that would reduce costs, cut carbon, and keep facilities running smoothly for the community.

Find out more about our pump services here

Lee began by conducting a comprehensive assessment of the pool’s fluid power equipment. He identified worn surfaces and reduced flow efficiency as key contributors to energy waste and higher running costs. Rather than recommending costly pump replacements, Lee looked for a smarter, more sustainable option.

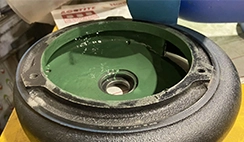

That’s when he contacted Henkel’s Technical Sales Engineer, Danny Aspey. Together they explored whether a Loctite protective coating could restore the pumps and deliver the performance improvements needed. After reviewing the options, the team agreed on LOCTITEׅ® PC 7255, a WRAS approved, high-performance coating specifically designed for pump internals.

Once applied, the coating rebuilt worn surfaces, protected against future wear, and improved overall flow efficiency. This extended the service life of the pumps and reduced the need for disruptive maintenance.

The results speak for themselves, £8,500 save annually in energy costs form just one pool, 6 tonnes of CO2 reduced every year, improved pump reliability and extended uptime, and reduced maintenance and lower long-term costs.

By working closely with the council, Henkel and Lee delivered a solution that not only tackled immediate cost pressures by also supported the council’s wider sustainability goals.

For public pools and leisure centres, this case shows what’s possible: sustainability without compromise. Lowering energy use, saving money, and keeping facilities running reliably for the community.