Linear and Automation Services Examples:

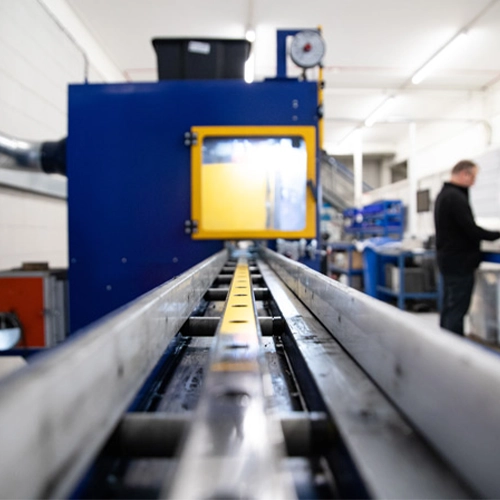

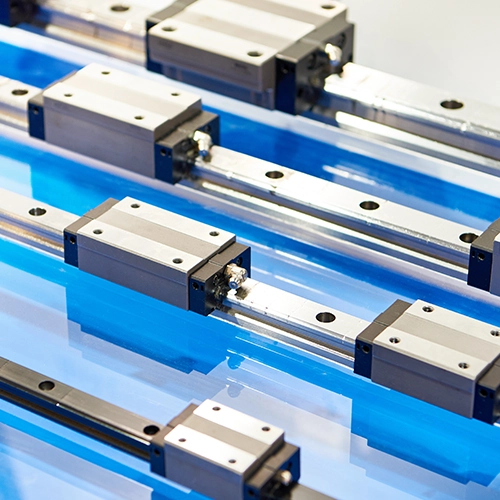

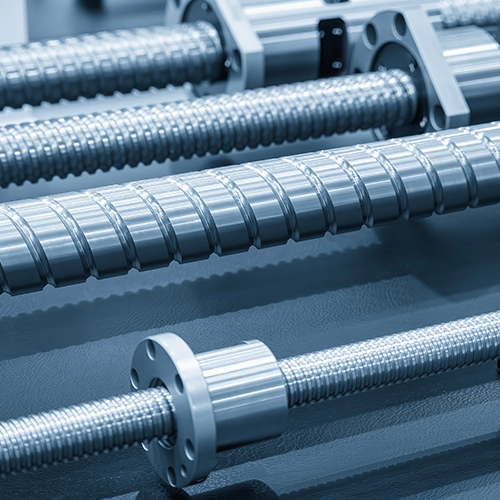

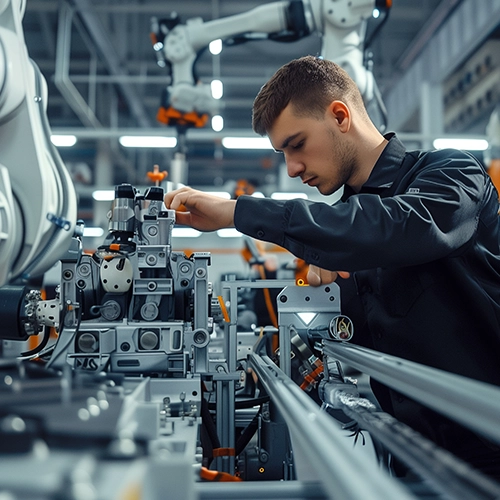

Linear Guide Kitting & Assembly

The customer was experiencing regular failures and damage to their systems as the process forces and system stresses were too high for the guide system in its existing arrangement.

- Eventually, we were able to advise a new layout more evenly distributing the loads across the guide elements, resulting in an expected lifetime many times longer than would be expected with the existing setup.

Acorn can help solve existing problems but also support you at the design stage to help ensure your systems have the longest life with the ultimate performance required in the most economical way