How to keep your fans spinning for longer

Industrial fans are a critical piece of machinery in every industry. Tasked with ensuring air circulation, as well as being a central part of any HVAC system, fans play a vital role in almost every business.

When it comes to downtime, there is no tolerance. A fan breakdown could cause anything from unpleasant working conditions to a complete halt in production.

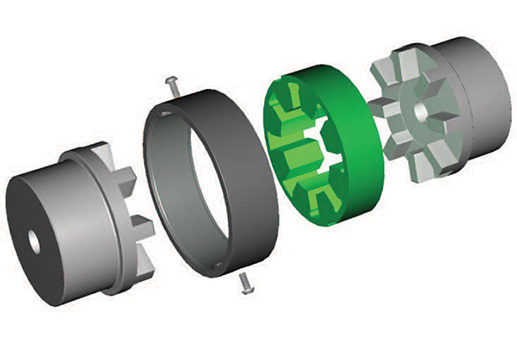

Falk Wrapflex® couplings offer a state-of-the-art solution which helps to optimise industrial fan uptime in four key areas:

Replace-in-place design

Replace-in-place design

Falk Wrapflex couplings have a cutting-edge design which features a polyurethane elastomeric element which is split, meaning that it can be replaced in situ. This reduces downtime when replacement is required as there is no need to remove the hubs or re-align the motor or shafts.

Reduced maintenance

The lubrication free design of Wrapflex couplings means that maintenance requirements are greatly reduced, as well as the associated cost savings attached to not having to purchase or apply lubrication. Downtime to perform maintenance is therefore further reduced, allowing more time for operation.

Extended element life

Wrapflex couplings have a patented element and hub design which provides an extended element lifespan. The design also features improved element flexibility, making installation easier and quicker than ever before.

Protect connected equipment

These jaw couplings also help to protect surrounding machinery from damage caused by shock loads and vibration. This helps to extend equipment life, reducing costs for the business and optimising production uptime.

For more information about Falk Wrapflex® couplings, contact our dedicated couplings division today.