Enhancing Conveyor Performance with a Robust SKF-Based Seal Solution

A global technology company operating multiple intralogistics centres was experiencing persistent failures on conveyor geared motors, with units regularly leaking oil from the gearbox within only a few months of service. The source of the issue was traced to the original sealing arrangement. As the seals or seal positions began to deteriorate, oil would escape from the gearbox and drip directly onto product.

The problem had become so common that the customers had adapted their maintenance process to accommodate it, installing oil catchers beneath the units and carrying out regular visual inspections. Although these temporary measures kept production moving, they added unnecessary work and created the risk of contamination, reduced uptime and inconsistent performance across the conveyor lines.

When the engineering team approached Andy Fletcher, ACORN’s Bearing Product Manager for support, our specialists worked closely with the customer and SKF to understand the conditions that were driving such frequent failures. It became clear that the seal interface simply wasn’t robust enough for the duty cycle and operating environment of the conveyors.

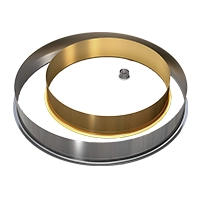

ACORN developed a redesigned sealing arrangement that replaced the existing interface with a configuration built around a standard SKF lip seal and an SKF speedi-sleeve. This pairing provided a higher-quality running surface and a more resilient sealing contact than the original design. It also ensured ease of replacement and long-term availability, supporting the customer’s maintenance strategy and alignment with trusted SKF components.

around a standard SKF lip seal and an SKF speedi-sleeve. This pairing provided a higher-quality running surface and a more resilient sealing contact than the original design. It also ensured ease of replacement and long-term availability, supporting the customer’s maintenance strategy and alignment with trusted SKF components.

Since installation, the new arrangement has delivered continuous trouble-free operation. There has been no recurrence of leaks, and the customer has been able to remove all oil-collection canopies that were previously required. The improved sealing performance has restored confidence in the geared motor units and reduced the burden of routine inspection, allowing the engineering team to focus on value-adding maintenance rather than reactive interventions.

This project demonstrates how collaborative engineering, strong supplier relationships and a willingness to rethink designs can deliver meaningful improvements in reliability. By bringing together customer insight, ACORN’s technical expertise and SKF’s high-performance components, we were able to provide a solution that performs better than the original equipment and supports long-term operational uptime.