Timken and the Tapered Roller Bearing: The Full Story

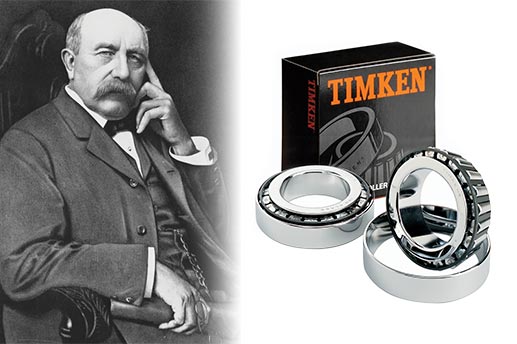

Since its invention in 1898 by Henry Timken, the tapered roller bearing has become a staple in many industries, with applications across the globe relying on the tapered roller bearing for reliable operation. But where did this bearing come from, and how has it evolved over time?

In this article, we'll take you through the invention and evolution of the tapered roller bearing, from its initial design over a century ago, through to its modern day usage. We'll also take a look at some of the benefits of choosing tapered roller bearings for your application.

The invention of the tapered roller bearing

Henry Timken was born in 1831 in Bremen, Germany, before emigrating to the United States at just seven years old. His family ran a farm in Sedalia, Missouri, where Henry worked in his early years.

Henry Timken was born in 1831 in Bremen, Germany, before emigrating to the United States at just seven years old. His family ran a farm in Sedalia, Missouri, where Henry worked in his early years.

Henry left the farm to become an apprentice, working under renowned carriage maker Caspar Schurmeier. After completing his training and working for Caspar for a number of years, Henry opened his own carriage building business in 1855.

Not one to follow the crowd, Henry began working on ways to improve the carriages that he was building. He rose to fame in 1877, when he invented and patented the 'Timken Buggy Spring', which quickly gained popularity around the world and was in high demand.

Henry then began looking for ways to improve his wagons' wheels. It was during this time that he first began to experiment with the tapered roller bearing, which would go on to become his most famous invention. The design evolved until it was finally patented in 1898.

The tapered roller bearing reduced friction in the wheels of wagons, enabling the load to transfer smoothly between the axle and the frame. This reduced downtime and maintenance requirements of the wagons, as well as requiring less mules to pull the wagons.

As more people heard about the new invention, popularity soared. Orders began coming in from across the United States, and even throughout the world. Staggered by the popularity of his invention, Henry Timken founded the Timken Roller Bearing Axle Company a year later, in 1899. And the rest is history.

The evolution of the taper roller bearing

The first Timken taper roller bearing quickly soared in popularity, with demand across the globe. By 1923, 25 years after the invention of the tapered roller bearing, 90% of the United States' bearings were produced by Timken. The bearings could be found on cars, trains, tractors, conveyors, elevators and even space shuttles. This popularity demonstrates the innovation that Henry Timken had brought to the world.

The original design of the tapered roller bearing has remained relatively unchanged since its invention over a century ago. However, there have been some advancements and refinements to the design over time. For example, adding a double, or even a quadruple row of rolling elements increases the load carrying capacity of the tapered roller bearing, whilst keeping axial space to a minimum.

The original design of the tapered roller bearing has remained relatively unchanged since its invention over a century ago. However, there have been some advancements and refinements to the design over time. For example, adding a double, or even a quadruple row of rolling elements increases the load carrying capacity of the tapered roller bearing, whilst keeping axial space to a minimum.

These further developments mean that tapered roller bearings can now be used in a wide range of applications, across almost every industry.

Where are tapered roller bearings used today?

Although tapered roller bearings are now manufactured by companies across the globe, Timken remains the world's largest producer of tapered roller bearings. Timken's products can be found in applications all over the world, in a wide range of industries.

Fast forward to 2022, and you'll find tapered roller bearings used in almost every conceivable application. They can be found in cars, planes, trains, boats, construction equipment and agricultural machinery. They're also used in elevators, conveyors and wind turbines - to name but a few.

It's difficult to find an industry in which tapered roller bearings would not be of use, as they are extremely versatile and solve many application challenges.

Benefits of tapered roller bearings

As you would expect with a bearing that is so popular, there are many benefits of using tapered roller bearings in your application. Let's take a look at just some of the benefits of tapered roller bearings.

As you would expect with a bearing that is so popular, there are many benefits of using tapered roller bearings in your application. Let's take a look at just some of the benefits of tapered roller bearings.

- Accommodates combined loads: One of the key benefits of a tapered roller bearing is that it can accommodate combined radial and axial loads. This makes them ideal for applications which are subject to both radial and axial loads.

- Reduced downtime and maintenance: As the bearings have a longer life span than other types of bearings, this reduces the amount of time needed for maintenance and repairs.

- Increased load capacity: Due to the design of the bearings, they are able to carry heavier loads than other types of bearings.

- Reduced friction: The bearings reduce friction in the application, which leads to a smoother operation and less wear and tear.

- Suitable for a wide range of applications: Thanks to their versatility, tapered roller bearings can be used in almost any application.

- Stands up to harsh operating environments: These bearings are able to withstand high levels of heat, moisture and other harsh conditions.

Why choose Timken tapered roller bearings?

As you can see, there are many benefits of installing a tapered roller bearing in your application. But why should you choose Timken for your tapered roller bearings?

As the world's largest producer of tapered roller bearings, Timken is the obvious choice when you're looking for a manufacturer. With over 100 years of experience in manufacturing tapered roller bearings, Timken knows what it takes to make a high quality, reliable bearing that will stand up to the harshest environments.

As the world's largest producer of tapered roller bearings, Timken is the obvious choice when you're looking for a manufacturer. With over 100 years of experience in manufacturing tapered roller bearings, Timken knows what it takes to make a high quality, reliable bearing that will stand up to the harshest environments.

Not only that, but Timken tapered roller bearings have been carefully designed to stand up to even the harshest of operating environments. This means that Timken tapered roller bearings can be used in arduous industries such as agriculture, mining and quarrying and recycling.

In summary

Henry Timken's invention of the tapered roller bearing revolutionised the transportation industry and has found its place in bearing history. With their long life span, reduced downtime and maintenance, and increased load capacity, tapered roller bearings are a reliable and efficient option for use in every industry.

For more information about Timken tapered roller bearings, or to find out if this is the right bearing for your application, give our knowledgeable sales team a call today.