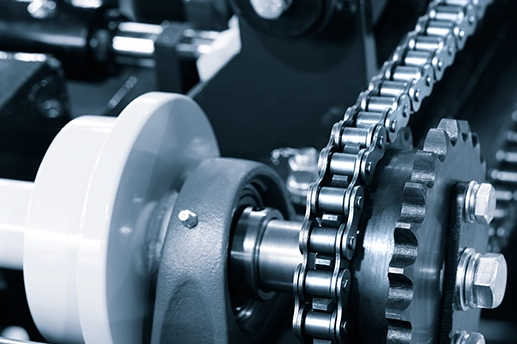

Top 5 Tips for Roller Chain Maintenance

When it comes to keeping your roller chain drive running smoothly, a little attention goes a long way. Whether you’re operating in clean conditions or gritty, abrasive environments, regular maintenance is key to keeping downtime at bay and getting the most out of your chain.

Here are the top 5 things to stay on top of:

1. Fit the Right Chain for the Job

This one’s simple but crucial. Using the wrong type of chain for your environment is a fast track to unnecessary wear and potential failure. Dusty or abrasive applications? Go for heavy-duty or corrosion-resistant options such as ProTorque Plus chain with Nickel Plating, or Tsubaki Titan Chain. Working in damp or clean environments? Try the Renold SD Stainless Steel range to avoid rusting while adhering to strict safety standards. By choosing the best chain from the outset, you’ll save a lot of hassle and unplanned downtime later down the line.

2. Inspect Early, Monitor Often

Your chain needs checking after the first 50 hours of run-in time. That’s the ideal window to ensure everything has bedded in properly and to spot any early signs of trouble. Using a chain wear indicator is a quick and easy way to monitor wear. After this, the inspection schedule will depend on the drive’s workload. In heavy shock loads or severe conditions, chain should be checked on average every 200 hours. Whereas in standard conditions, it is recommended chain is inspected every 500 hours.

Red flags to look out for include:

- Chain jumping or excessive vibration

- Noise or vibrations

- Sprocket wear or misalignment

- Build-up of debris between chain and sprocket

- Over or under-tensioning

- Any signs of interference or incompatible components

By spotting these issues early, any failures and unplanned downtime can be mitigated before it becomes a bigger issue.

3. Check Tension and Alignment

If your chain is too tight it’ll wear out quicker, and if it’s too loose, you risk slippage and reduced performance of chain drives. Getting tension right keeps everything running efficiently and extends chain life.

Sprocket alignment is also vital. Misaligned sprockets put uneven pressure on the chain and lead to premature wear. A properly aligned setup spreads the load evenly across the chain and helps you avoid headaches later. Using tools such as the SKF TKBA 31 alignment tool provides an easy and accurate pulley and chain drive alignment.

4. Don’t Forget About Lubrication

If your chain requires lubrication (unless you are using a maintenance-free option, most chains do), make sure it’s getting enough of the right type. Proper lubrication reduces frictions, prevents rust, and keeps the system running quietly. Under lubricated chains wear out quickly. If you take the time to do it properly, it will save you in time and money. There are many ways to efficiently lubricate chain, including brushes, drip lubrication, oil streams, or hands-free systems such as RotaLube Inaccessible Chain Lubrication Kit. Depending on your application, the most effective method will vary.

5. Use Chain Guards

Safety guards don’t just protect people, they help keep your chain free from contamination. Dirt, dust, and debris can quickly degrade a chain, especially if they work their way between the chain and sprocket. Clean both regularly and inspect for damage in order to keep your equipment reliable and your team safe.

The best way to extend the life of your roller chain is to start with the right one, keep it clean, well-lubricated, and properly aligned - give it a regular once-over to catch any issues early. It’s about working smarter, not harder.

Check out our range of roller chains to buy here

If you need a hand choosing the right chain or assessing your drive, contact our Power Transmission Expert who can help you to keep your downtime down and uptime up.