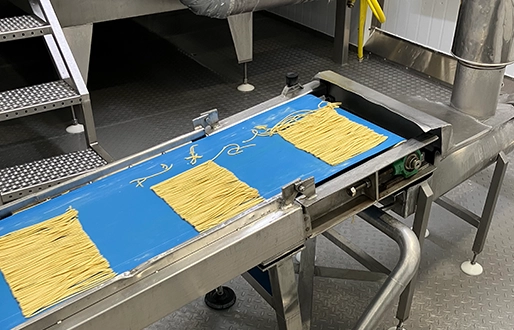

CASE STUDY: How a Simple Bearing Upgrade Increased Uptime by Over 6x on Noodle Production Line

When a major food production company started experiencing regular bearing failures – anywhere between two weeks and six months – they knew something had to change. The constant downtime was affecting output and increasing costs. That’s when they contacted ACORN’s Bearing Product Expert, Andy Fletcher.

Andy got straight to work. With a full production line mapping in hand, he quickly identified where improvements could be made. As part of ACORN’s value-added services, this kind of in-depth analysis helps customers make confident, cost-effective decision, and Andy had the right solution.

The root of the issue was standard generic brand bearings weren’t cutting it in a demanding food production environment. Andy recommended a switch to SKF Food Line bearings units, featuring a back seal, end cap, and stainless-steel solid oil deep groove ball bearing insert. These are designed specifically for hygiene-critical operations and built to last.

After upgrading the entire noodle production line, the improvement was immediate. The customer saw a full 12 months of continuous service life, cutting downtime and maintenance by 96%.

By making a smart switch to more durable, food-safe components, this business has increased uptime, saved money, and gained peace of mind. Knowing they’re working with the right partner for long-term performance.