What Industries and Applications is Gates PolyChain used in?

Many industries require the highest safety standards when it comes to their working environments. This is particularly essential for ATEX (explosive) environments. These environments can’t afford any level of potential ignition, which means it is essential that all products offer 100% ATEX safety insurance.

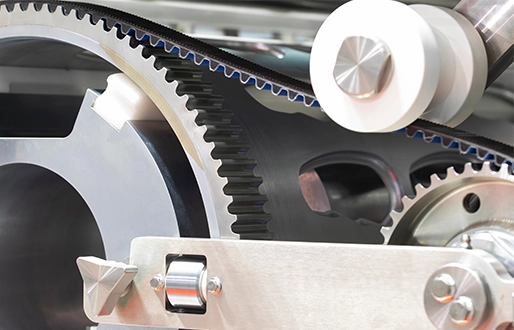

Industrial timing belts in this environment can be tricky. Although they offer the best transmission of power, rubber or polymer materials can build up static charge, a huge no-no for any explosive environments. However, there are solutions and alternatives to keep machinery working at its most efficient, even in ATEX environments.

Find out more about the causes of timing belt failure here

For example, the Gates Poly Chain® Carbon Volt® belt is the safest and strongest option for explosive settings. These belts meet the ISO 9563 standard for static electricity conduction over the complete lifespan of the belt (so no need to worry as it wears or comes to the end of its lifespan). This is because they are made with conductive carbon fibres to safely bleed off static electricity, preventing sparks. They are also a durable option with a high load capacity, chemical resistance, and long life span thanks to the carbon tensile cords and polyurethane body.

But what does this mean in practice? Let’s take a closer look at how Carbon Volt belts help keep critical industries running safely and efficiently.

Oil & Gas

Pumps, compressors, and drilling equipment in the oil and gas sector often run in volatile atmospheres filled with flammable vapours. Traditional belts risk static discharge, but Carbon Volt belts eliminate this hazard, while also resisting the harsh chemicals common in extraction and refining environments.

Chemical refinery

In chemical plants, vapours and solvents create a constant risk of ignition. Belts must not only handle static safely but also withstand chemical exposure without degrading. The polyurethane and carbon fibre construction makes Carbon Volt belts ideal for agitators, mixers, and fans in this sector.

Grain processing

Grain dust is one of the most explosive substances in industrial environments. Conveyors, elevators, and mills all need drives that will not produce sparks. The static-dissipating properties of Carbon Volt belts make them a safer, cleaner alternative to chain drives, reducing ignition risks while ensuring smooth, reliable power transmission.

Automotive paint line

Automotive paint shops are filled with flammable fumes, making static sparks a constant danger. Carbon Volt belts provide a dry, oil-free, spark-free drive solution for conveyors and robotics, ensuring smooth production with no contamination risks.

Labelling line

High-speed labelling lines are extremely sensitive to static interference, which can misapply labels or damage electronics. These conductive belts safely dissipate charges, preventing both safety hazards and production issues in fast-moving packaging environments.

Energy transformation

In biomass plants, power stations, or renewable energy facilities, dust and vapours are often present alongside heavy-duty equipment. Carbon Volt belts combine ATEX compliance with high load capacity, making them suitable for demanding conveyor, pump, and cooling applications.

Sugar industry

Sugar dust is notorious for explosion hazards. Processing, refining, and conveying sugar requires antistatic solutions that prevent ignition sources. Carbon Volt belts are resistant to the sticky, abrasive nature of sugar, while eliminating static buildup throughout their working life.

Animal feeding

In feed mills and animal nutrition plants, fine dust from grains and additives can easily become explosive. Carbon Volt belts offer a safe, maintenance-free alternative for conveyors and mixers, reducing risks without requiring lubrication.

Furniture factory

Woodworking generates fine sawdust, a highly flammable material. Extraction fans, conveyors, and processing equipment in furniture production benefit from Cabon Volt belts, which prevent sparks and withstand heavy-duty use.

Plastics processing

Plastics manufacturing often involves both dust and fumes that pose ignition risks. Extruders, conveyors, and cooling systems run more safely with belts designed to conduct static electricity away reliably. Carbon Volt belts also resist chemicals and heat, ensuring durability in tough conditions.

When it comes to ATEX environments, safety and performance cannot be compromised. The Gates Poly Chain Carbon Volt belt is more than just a drive solution; it’s peace of mind. As a direct replacement for chains and standard belts in explosive or sensitive environments. They combine the strength of chain drives with the cleanliness and static safety belts, making them especially valuable in industries where dust, fumes, or vapours can ignite.

If your operations run in explosive atmospheres, isn’t it time to switch to a drive system that’s built for the challenge?