What is the Difference Between a Linear Guide and a Roller Guide?

Choosing the right linear guide system can be challenging, but it’s crucial for keeping your machinery performing at its best. Precision, efficiency, and reliability all depend on selecting the right components for your application.

Both linear ball guides and roller guides reduce friction and enable smooth linear motion, but their internal design differences make them better suited to different tasks. Here’s how they compare, and what that means for your machinery.

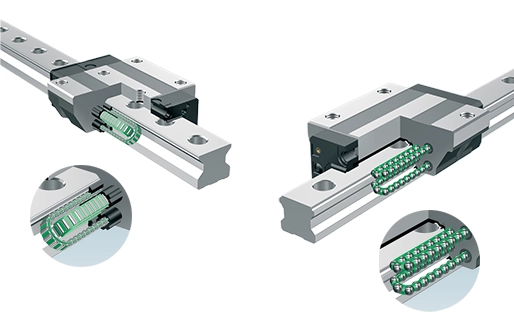

1. Rolling element

The primary difference lies in the rolling element itself.

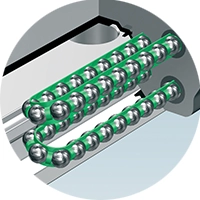

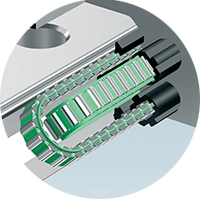

- Ball guides use spherical balls that make point contact with the raceway.

- Roller guides use cylindrical rollers that make line contact with the raceway.

This difference in contact geometry significantly affects performance in terms of load capacity, rigidity, and motion characteristics.

2. Load capacity and stiffness

Ball guides offer excellent performance under light to medium loads and allow for a small degree of elasticity under pressure.

Roller guides, on the other hand, have a larger contact area, resulting in higher load capacity and stiffness. This makes them ideal for machines that require high rigidity and minimal deflection, such as machine tools or heavy-duty automation systems.

3. Friction and speed

Ball guides have lower roller friction, allowing for higher speeds and smooth movement under light loads. Roller guides typically have slightly higher running resistance and lower maximum speeds than comparable ball guides.

4. Shock and vibration

If your application involves shock loads or vibration, roller guides are the better option. Their line contact gives them superior shock resistance compared to ball guides, which are more prone to damage from impact due to point contact.

5. Life and wear

Because of their lower contact stress, roller guides typically offer a longer service life under high or static loads.

Ball guides excel in dynamic, moderate‑to‑high‑speed applications and can handle significant loads, but at very high loads or shocks, contact stress becomes the life‑limiting factor.

6. Misalignment tolerance

Ball guides are slightly more forgiving with slight misalignment more effectively, thanks to their point contact and elastic deformation.

Roller guides, however, demand precise alignment and a rigid mounting structure to perform correctly.

7. Contamination sensitivity

Both systems require good sealing and regular lubrication to perform reliably. Roller guides have tighter internal clearances, making clean lubrication and effective sealing even more important to prevent premature wear.

Typical Applications

- Ball linear guides: general automation, CNC axes, 3D printers, pick-and-place systems, and packaging. Typically chosen for their speed, low friction, and cost-effectiveness.

- Roller guides: machine tools, presses, gantry systems, precision inspection equipment, semiconductor equipment, and metrology applications. Preferred for their rigidity, heavy-load capacity, and excellent rigidity and straightness under load.

How to choose

Your decision should be based on what’s most critical to your application:

- Priority: speed, low friction, economic running – ball linear guide

- Priority: Rigidity, high load, precision under load – roller guide

- Priority: Short-stroke precision and metrology-grade smoothness – crossed-roller slide

Talk to the experts

Not sure which system suits your machine best? Our dedicated linear division is here to help.

At ACORN, we stock an extensive range of THK, REXROTH & INA linear guide systems, including both ball and roller guides, ready for immediate despatch. Meaning we offer the broadest range of linear stock to ensure we can find you the correct solution. Whether you’re replacing existing components or specifying a new system, our experts can help you select the right linear solution to keep your machines running better, for longer.