Rewinding is a form of electric motor refurbishment. For large motors, and some small precision motors, it generally works out more cost-effective for a company to rewind an existing motor than to source a replacement.

Rewinding is commonly performed on electric motors attached to a wide range of applications, such as conveyors, pumps and fans. It is a useful tool across many different industries, including automotive, steel, food & beverage and material handling. Wherever there is a shaft to turn, an electric motor is involved!

As well as replacing the brushes and windings, rewinders will also need to replace the bearings and seals. Motor burn-out is often caused by over-lubrication of the bearings, which leads to the ingress of grease onto the windings.

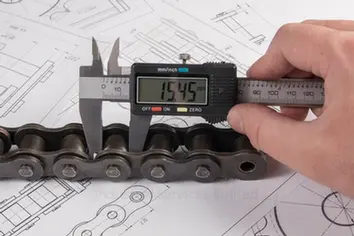

When removing and replacing the bearings, there is an inherent risk of damage to the shaft and motor. This makes proper removal and refitting of the bearing essential, to avoid the need for expensive repairs or replacement. Bearing dismounting and fitting tools can help with this.

Replacement parts also need to be fit for purpose. For example, any bearings that are replaced will often need to be electrically insulated. This prevents arcing which can destroy bearings and cause the motor to fail beyond repair.

Time is also of the essence during an electric motor rewind. Cost is of great importance to customers, so to keep labour costs low, it needs to be quick to remove and replace bearings. It also takes time to dismantle and inspect the motor, which costs the customers in downtime. Condition monitoring tools can enable the motor to be inspected dynamically, without any downtime required.

ACORN can help you to find solutions to the challenges you face, allowing you to find the perfect balance between quality and cost. Contact us today to discuss your requirements.

Related articles

Lining up for success: Alignment tools for the rewinders industry

Don't wind up with damage: Fitting tools for the rewinders industry

Clive recommends his favourite maintenance product for the rewinder industry