Does sustainability really matter when sourcing replacement machine components?

Picture this: a bearing fails on the most important machine in your biscuit factory, and production grinds to a halt. Downtime is mounting up by the second. Already tight deadlines are at risk of being missed, and the entire workforce is standing around with nothing to do.

You need to find a replacement bearing, and fast. You check the load requirements of the machine, the operating speed and the environmental conditions. Just as you begin your Google search, someone mumbles something about sustainability. Surely one bearing can’t matter that much? How much impact could something so small really have?

Many companies have strict government targets to meet when it comes to their pollution or CO2 emissions. In this article, we look at the sustainability challenges that you face when selecting replacement machine components and simple solutions that could boost the sustainability of your business.

Problem 1: Energy efficiency

Global warming is a topic that most people have heard about, thanks to its widespread reporting in news outlets. However, many people do not fully understand the effects of global warming or the impact that individual actions can have.

Energy wasted during machine operation causes excess CO2 and other greenhouse emissions, which gather above the earth’s atmosphere. These emissions then form a blanket, preventing heat from escaping into space. This creates the greenhouse effect, heating our atmosphere.

This greenhouse effect causes a rise in the earth’s temperature, causing polar ice caps to melt, damaging ecosystems across the globe and causing extreme weather, such as droughts and wildfires, which threaten human health.

With 18% of total UK CO2 emissions produced by businesses, there is a lot that we can do to help reduce the effects of global warming. (Department for Business, Energy and Industrial Strategy, 2019)

Selecting energy-efficient components can dramatically reduce energy consumption. For example, SKF E2 bearings have been designed to reduce frictional moment by a minimum of 30%, lowering the energy required for operation.

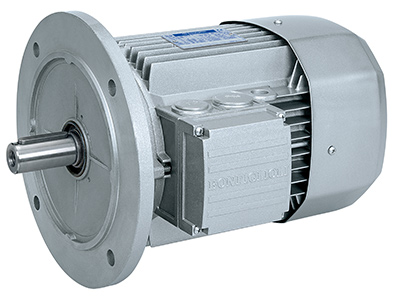

When it comes to drives, IE3 electric motors can be chosen over IE2 motors to deliver increased levels of efficiency. Bonfiglioli and TEC Motors both offer high-quality IE3 electric motors, which can improve the sustainability of your business.

Tsubaki GT4 Winner chain is another product which excels when it comes to energy efficiency, although the energy savings with this chain come mainly from production, combined with its long lifespan. Tsubaki GT4  Winner chain reduces CO2 emissions by 66% throughout its lifetime, between its environmentally-friendly materials, processing and scrappage. This is mainly due to its extended service life, as replacement requirements are few and far between.

Winner chain reduces CO2 emissions by 66% throughout its lifetime, between its environmentally-friendly materials, processing and scrappage. This is mainly due to its extended service life, as replacement requirements are few and far between.

Correct alignment of belt-driven applications & shaft alignment of direct-driven applications will improve energy efficiency. Any misalignment will result in leakage of power and increased costs through both energy wastage and premature component failure. Laser alignment tools such as the Optibelt Laser Pointer II will help to ensure that belt drives are effectively aligned, helping to make operation as efficient as possible.

Lubrication also plays a huge part in maintaining machine efficiency. It is essential to ensure that you are using the correct lubricant for the application and that the right measurement is being dispensed at the correct intervals. Over-greasing results in unnecessary heat being created inside the bearing owing to additional friction, which ultimately reduces its life. Under-lubrication will cause a similar result.

Pneumatic systems are commonly found in material handling applications, but their energy consumption is high due to the continuous supply of energy required to maintain a constant pressure. Changing a pneumatic system over to an electrical machine automation solution can reduce energy wastage, as energy is only needed during a movement. Electrical machine automation systems also provide greater flexibility for the business, as they are able to be reprogrammed without having to make mechanical adjustments. Modular Machine Automation Systems help to reduce the total cost of ownership to the business, thanks to their lower design costs, reduced energy consumption, and minimal maintenance requirements, making them an all-around benefit to the business.

Pneumatic systems are commonly found in material handling applications, but their energy consumption is high due to the continuous supply of energy required to maintain a constant pressure. Changing a pneumatic system over to an electrical machine automation solution can reduce energy wastage, as energy is only needed during a movement. Electrical machine automation systems also provide greater flexibility for the business, as they are able to be reprogrammed without having to make mechanical adjustments. Modular Machine Automation Systems help to reduce the total cost of ownership to the business, thanks to their lower design costs, reduced energy consumption, and minimal maintenance requirements, making them an all-around benefit to the business.

Condition monitoring is a valuable tool in identifying where energy is being lost within an application. The measurement of anticipated problems also enables preventative measures to be taken in advance of any potential situation causing damaging failures and stoppage.

Condition monitoring is a valuable tool in identifying where energy is being lost within an application. The measurement of anticipated problems also enables preventative measures to be taken in advance of any potential situation causing damaging failures and stoppage.

SKF manufactures a comprehensive range of condition-monitoring tools which can identify any lost energy. For example, SKF TMSU1 is an ultrasonic leak detector which uses ultrasound to check for air leaks which could be causing detriment to energy consumption. SKF TKED 1 allows the user to detect electrical discharge, where the electrical current may be causing damage to surrounding bearings through electrical erosion.

Problem 2: Landfill

In 2016, 52.3 million tonnes of waste was sent to landfill in the UK alone. This equates to 24.4% of all UK waste, an astounding statistic. (Department for Environment, Food & Rural Affairs, 2019) Non-recyclable machine components generally end up in landfill, where they take hundreds or even thousands of years to decompose.

Some types of plastic, for example, can take up to 1,000 years to decompose in a landfill site, and the UN has predicted that by 2050, there will be more plastic in the sea than fish. This poses a huge risk to marine life, which is possibly the biggest impact of plastic disposal.

Waste which decomposes in landfill sites releases toxins which seep into the soil and groundwater, as well as releasing greenhouse gases such as carbon dioxide and methane into the air as they break down.

Moving towards a circular economy will dramatically reduce the amount of waste that is sent to landfill. This involves re-using, repairing and recycling materials wherever possible. Look for components which are manufactured using recycled materials, which are able to be recycled again at the end of their service life.

Moving towards a circular economy will dramatically reduce the amount of waste that is sent to landfill. This involves re-using, repairing and recycling materials wherever possible. Look for components which are manufactured using recycled materials, which are able to be recycled again at the end of their service life.

SKF Food Line bearings are an excellent example of components which utilise the circular economy. These units do not contribute to landfills, as 59% of the unit is recyclable, and 41% is energy recovered.

Auxiliary products such as cleaning wipes, gloves, and containers used for maintenance are also a large source of landfill, as they are frequently unable to be recycled. Selecting low-maintenance or maintenance-free components will reduce your consumption of auxiliary products, meaning that there is less to dispose of.

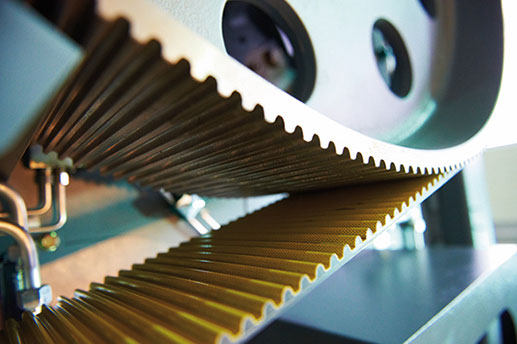

Switching your chain drive to a high-power polyurethane belt drive can eliminate maintenance requirements, reducing the use of disposable maintenance items, along with the time and cost associated with performing maintenance tasks.

Switching your chain drive to a high-power polyurethane belt drive can eliminate maintenance requirements, reducing the use of disposable maintenance items, along with the time and cost associated with performing maintenance tasks.

New legislation is currently being introduced to avert the use and disposal of harmful materials, which have a negative impact on both the environment and health. REACH (opens new window) (Registration, Evaluation, Authorisation and Restriction of Chemicals) is the key driver for this. Businesses need to be fully aware of this impact and consider best practise wherever and whenever possible.

Problem 3: Water pollution

Rivers and seas across the globe are becoming increasingly contaminated by chemicals, waste and other pollutants. Every year, around one billion people become ill as a result of consuming unsafe water. (Natural Resources Defense Council, 2019) Contaminated water destroys ecosystems by reducing water oxygen levels and poisoning aquatic life, making survival increasingly difficult.

Lubrication can enter the water stream as a waste product after washdowns or as a result of leakages. Washdowns are common in the food & beverage and pharmaceutical industries, where impeccable hygiene is essential.

Lubrication can enter the water stream as a waste product after washdowns or as a result of leakages. Washdowns are common in the food & beverage and pharmaceutical industries, where impeccable hygiene is essential.

In areas subject to frequent washdowns, specially designed housed bearing units such as SKF Food Line help seal the lubricant, preventing leakage during cleaning. SKF Food Line units save an average of 78kg of grease per year for an average plant, meaning that there is also less grease to be disposed of at the end of their service life.

Bearings which are re-lubrication free such as NSK Molded Oil bearings, also provide a good level of defence against water pollution, as the lubricant is sealed securely within the component to prevent grease leakage. This also removes the need for downtime to carry out maintenance and the associated labour costs.

Bearings which are re-lubrication free such as NSK Molded Oil bearings, also provide a good level of defence against water pollution, as the lubricant is sealed securely within the component to prevent grease leakage. This also removes the need for downtime to carry out maintenance and the associated labour costs.

Another way to reduce the amount of lubrication that finds its way into the water system is by using automatic lubricators. These devices dispense the exact quantity of lubricant at the right intervals. Ensuring that the correct quantity is used every time means there is no wastage and less lubricant is washed from the equipment during cleaning regimes.

Conclusion

Sustainability is a critical consideration in all aspects of business. You can’t put a price on the importance of sustainability for protecting our planet for future generations. However, the cost of sustainable components and practices could easily mount up.

Luckily, ACORN is on hand to help you to find cost-effective ways to ensure that your business is as sustainable as possible, reducing your energy consumption, limiting your contribution to landfill, lowering your impact on water pollution and protecting the planet for decades to come.

For more information on sustainable components or for advice on how you can make your business more sustainable, contact your local ACORN branch today.

References

Department for Business, Energy and Industrial Strategy., (2019). Alternative Format 2018 UK greenhouse gas emissions: provisional figures – data tables [online] https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/790086/2018-provisional-emissions-statistics-one-page-summary.pdf

Department of Environment, Food & Rural Affairs., (2019). UK statistics on waste – February 2019 update [online] https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/784263/UK_Statistics_on_Waste_statistical_notice_March_2019_rev_FINAL.pdf

Natural Resources Defense Council., (2019) Water Pollution: Everything You Need To Know [online] https://www.nrdc.org/stories/water-pollution-everything-you-need-know

United Nations Environment Programme., (2019) UN Declares War On Ocean Plastic [online] https://web.unep.org/unepmap/un-declares-war-ocean-plastic