The History of Linear Actuators

Electric linear actuators are one of the most common components in modern industry, but did you know the underlying design has actually been around for many centuries? In fact, you might be surprised to learn that the roots of the linear actuator can actually be traced all the way back to the 17th century.

In this article, we'll take a closer look at the history of linear actuators, going right back to where it all began. After all, we need to understand the past to enable us to look to the future.

It all began with a piston

Take a closer look at the design of the linear actuator and you'll notice that it's actually based on a piston, which is driven by an electric motor.

Take a closer look at the design of the linear actuator and you'll notice that it's actually based on a piston, which is driven by an electric motor.

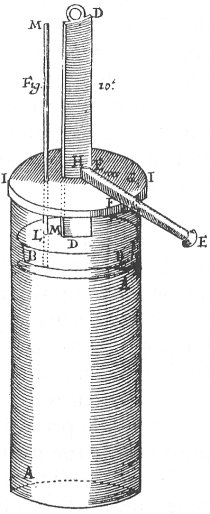

The first steam cylinder was designed by Denis Papin, a French physicist, and inventor, in the mid-1670s. This early design was used to create a reciprocating engine, which is a type of engine that creates linear motion using a piston.

In the steam cylinder, the steam created the energy that drove the piston. The steam engine was the first type of engine that could create linear motion, and this set the stage for a new future of the industry. With this new technology, factories could be built larger and production could be increased.

This marked the beginning of the industrial revolution, as production of goods was industrialised.

The development of the piston

By the 1800s, the first air compressor had been invented. These became widely used in industry, and in the early 1900s, the air compressor was combined with a piston to create the first ever pneumatic actuator.

The first time that a pneumatic actuator was recorded in use was during World War II. It was during this time that pneumatic actuators became widely known in the industry. Because of the demand in goods in World War II, these types of linear actuators began to be mass-produced for military use.

After the war, pneumatic and hydraulic actuation systems increased in popularity, and they began to be introduced into the automotive industry. It was here that they began to be used in braking systems within cars. This is because they could exert a high level of force without resulting in high levels of wear and tear.

As the years went on, pneumatic actuators gradually began to replace valves in pipes. In the 1960s, digital to pneumatic control devices were introduced. This enabled flow and pressure to be carefully controlled, ushering in a new era of efficiency for factories and production lines all over the world.

The start of linear as we know it today

In the mid-1900s, the mechanical linear actuator as we know it today began to emerge. The basic design of the mechanical linear actuator takes rotary motion converts this into linear motion to drive the actuator. There are a few ways in which this can be done:

In the mid-1900s, the mechanical linear actuator as we know it today began to emerge. The basic design of the mechanical linear actuator takes rotary motion converts this into linear motion to drive the actuator. There are a few ways in which this can be done:

- Screw - such as a ball screw, leadscrew or roller screw.

- Wheel and axle - such as a hoist, winch, chain drive, belt drive or rack and pinion.

- Cam

This conversion of rotary motion into linear motion formed the design of linear actuators for many decades to come, and this has continued to evolve over time.

The evolution of the electric linear actuator

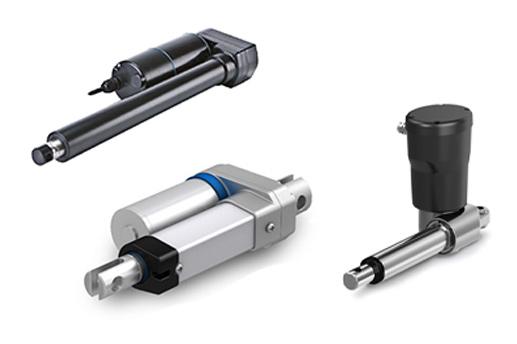

The underlying design of the electric linear actuator hasn't changed much since its invention. However, the controls and programmability has become more intricate, with the development of new technologies. This means that many actuators can now be controlled from a single panel, allowing them to be programmed quickly and easily.

The underlying design of the electric linear actuator hasn't changed much since its invention. However, the controls and programmability has become more intricate, with the development of new technologies. This means that many actuators can now be controlled from a single panel, allowing them to be programmed quickly and easily.

The electric linear actuator as we know it today was invented by Bent Jensen in 1979. Jensen was a Danish businessman who was trying to think of an idea to save his failing agricultural business. One day, whilst talking to an old friend who had a disability, Bent came up with the idea to develop an electric actuator that could adjust the wheelchair.

Since this pivotal moment over 40 years ago, electric linear actuators have continued to evolve as a result of developments in technology. They are now more accurate and more reliable than ever before, enabling precise positioning in almost every single industry.

What does the future hold for linear?

Today, electric linear actuators are used across many different sectors, and their uses can differ drastically depending on the industry. The main sectors that use electric linear actuators include:

- Construction

- Aerospace and defence

- Mining and quarrying

- Material handling

- Food and beverage

- Automotive and transportation

- Machine tools and metal fabrication

- Manufacturing

Check out our Linear Actuators here

It's undeniable that electric linear actuators have become an essential part of industry, enabling factories to increase production through automation. Previously manual jobs can now be done by machines thanks to developments in linear motion. But what does the future hold for linear?

In the future, we can expect to see new types of linear actuator being designed and manufactured. The advancement of electric actuators is a never-ending process, but one that is going at a rapid pace.

It's difficult to predict exactly what the future holds for the linear actuator industry. However, we can be sure that it will continue to improve and expand in all directions. Electric linear actuators have been improving our way of life for decades now, and this is unlikely to change any time soon.