Nadella AXNR Circular System

There is an ever-increasing demand on designers and machine manufacturers to develop movement solutions that are space saving, flexible, adaptable, efficient and customisable. The Nadella AXNR circular system is a further development of their FSR system designed to meet with those requirements, whether in the fields of packaging automation, general automation, food processing, medical equipment, printing machines and many other application areas. The Nadella AXNR system provides a tailor-made circuit that is supplied ready to use, thus reducing engineering time and cost.

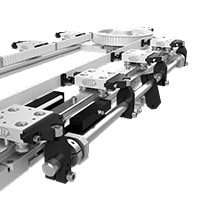

It combines the technologies of the Nadella Group and consists of several components like the Multi-Motion-Line circuits, the toothed belt drive motor, the LUBR lubricator for circular rails and the rod end connections.

Its main strengths are:

- Rollers with a load carrying capacity far higher than other similar sized components of the same class, thanks to Nadella linear motion technology.

- Steady and smooth movement of the entire system thanks to the special Durbal rod end connection between the toothed belt and the carriages.

- Aluminium alloy machining, which allows a compact space-saving system and offers a steady and easy-mounting solution. Fully customisable complete systems available thanks to AXNR flexible configuration.

So, let’s take a look in a bit more detail at the Nadella AXNR system

Carriages

Carriages utilise Nadella guide rollers supporting the load in all directions. Standard carriages with rollers in fixed position allow precise movement in the curved and in the straight sections of the guide rail circuit, unlike other systems that use recirculating ball guides. Carriage preload is factory set for a ready to use product. The carriage is equipped with two concentric guide rollers and two eccentric guide rollers. The eccentric guide rollers are mounted on the inner side of the circuit and allow preload adjustment, if required.

Carriages utilise Nadella guide rollers supporting the load in all directions. Standard carriages with rollers in fixed position allow precise movement in the curved and in the straight sections of the guide rail circuit, unlike other systems that use recirculating ball guides. Carriage preload is factory set for a ready to use product. The carriage is equipped with two concentric guide rollers and two eccentric guide rollers. The eccentric guide rollers are mounted on the inner side of the circuit and allow preload adjustment, if required.

The carriage body is based on an anodized aluminium plate. Additional machining, reference holes for example, can be easily incorporated. A special carriage design to best suit the requirements of the application is always possible.

Guides and guide rollers in stainless steel are part of the standard Nadella range. Carriages in an anticorrosion version can be easily configured. A fully stainless-steel solution can be provided on request

Power transmission

Carriage traction is based on toothed belt for quiet and maintenance free operation. The design of the AXNR focused on reducing the distance from the belt to the carriage. This minimizes the peak-load on the carriage connection at high speed during the transition from the radius to straight path.

Floating Connection

The toothed belt and carriages are linked by a floating connection. This provides a reliable movement along with compensating for the distance between the belt and carriage on the radius path. Two types of connectors available: A type based on rod end and B type based on direct engagement

Dynamic System

The drive pulley is directly mounted on the gear box output shaft for maximum integration. A high-quality gear box is used to achieve high dynamic and accuracy performance. Systems are delivered already configured with the proper interface for the customer specific motor. Specific gear boxes can be supplied on request

The drive pulley is directly mounted on the gear box output shaft for maximum integration. A high-quality gear box is used to achieve high dynamic and accuracy performance. Systems are delivered already configured with the proper interface for the customer specific motor. Specific gear boxes can be supplied on request

Aluminium Alloy Base

The module structure is made from aluminium. It is composed of the main plates supporting the pulleys and the profiles to support the linear guide rails. It’s a compact, space saving solution.

Lubrication

The Nadella LUBR system is an easy to mount solution. The lubrication oil stored in the foam is directly released to the surface of the guide rollers minimizing the oil consumption. The reservoir effect of the foam allows a significant reduction in the frequency of relubrication.

Positioning System

For applications that require precise positioning, the AXNR positioning system is available as an option The system is driven by an air cylinder located below the straight module beam. The cylinder rotates the indexer shaft, equipped with cam followers, that engage in the locating cam fixed on the carriages. Carriage location repeatability is +/- 0.05 mm. One or several positioning systems can be mounted on the module to index all carriages or some carriages only.

Inductive Proximity Sensors

As an option, if a reference point is required, inductive proximity sensors are available. The sensor can be easily fixed on the aluminium profile and reads a ferromagnetic target positioned on the carriage cam

Overall, the Nadella AXNR system is a high quality, flexible and adaptable solution to many of the challenges faced by today’s machine designers and builders.

I’ve left a significant advantage of this system to last; it is available on a lead time that is measured in weeks, not months. Prompt and timely delivery is often a critical factor in the choice that designers make.

If you think you may have an application for the Nadella AXNR system, then please make contact and put us to the test!